Polymers are large molecules, which are often built from repeated structural units. Many monomers may be connected through chemical reactions to form long chains. Because of their variety of usage and properties, polymers are important in several industries and play an important role in daily life, from everyday plastic materials to complex medical equipment.

- Polymers consist of long chains of molecules.

- Their monomers connect by polymerization reactions.

- The molecular mass of polymers varies with the structure.

- Polymers possess certain specific physical and chemical characteristics.

| GS Paper | GS Paper III |

| Topics for UPSC Prelims | Basic concepts of polymers, Types of polymers, Uses of polymers in everyday life and industry |

| Topics for UPSC Mains | Advanced polymer materials, Role of polymers in environmental sustainability, Application of polymers in medicine and technology, Challenges related to polymer waste management |

Classification of Polymers

Polymers are categorized based on several factors such as origin, structure, and behavior. These classifications of polymers determine the type of material to be used in an application.

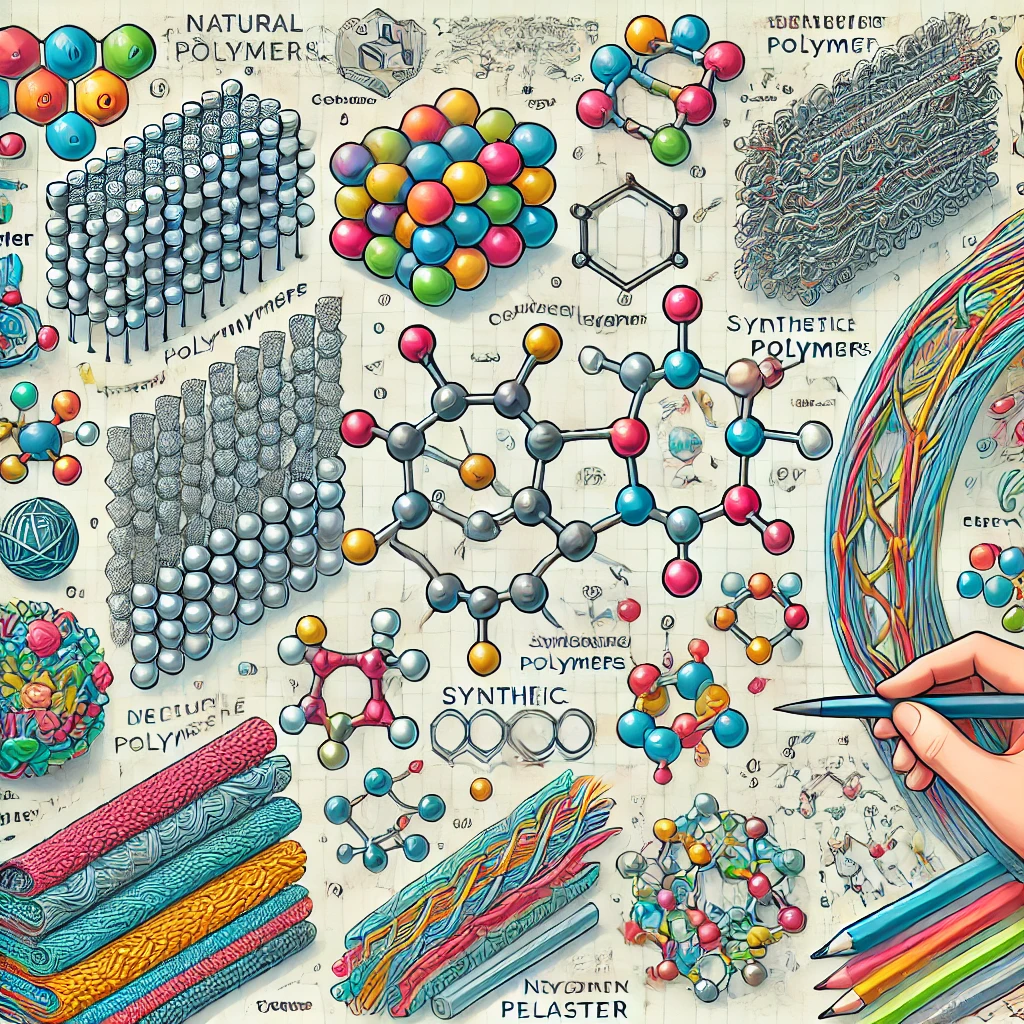

Origin-based Categorization

Polymers can be broadly classified into three types according to their origin:

- Natural Polymers: These occur naturally and exist in natural environments such as plants, animals, and even humans. Examples include cellulose, proteins, and natural rubber.

- Synthetic Polymers: Chemists synthesize these synthetic polymers chemically. Some of the most common synthetic polymers are nylon, polyester, and polystyrene, which industries widely use.

- Semisynthetic Polymers: These are chemically modified natural polymers, like cellulose acetate or vulcanized rubber. These kinds of materials are manufactured for a specific application by changing their natural feature.

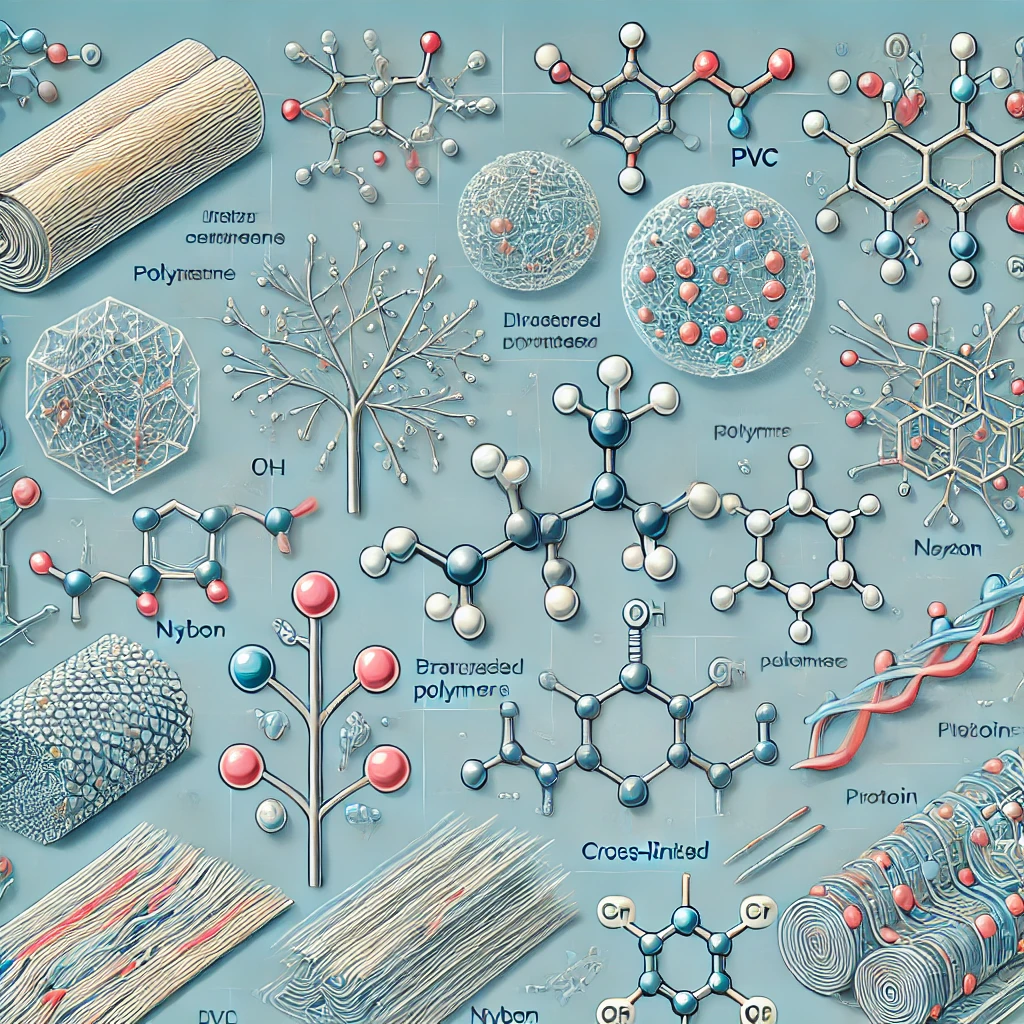

Classified on Basis of Structure

The structure of polymers dictates many of their properties. You can broadly categorize polymers according to their structural arrangement as follows:

- Linear Polymers: Their molecular structure has little or no branching; hence it appears straight in shape. Such type of simple, linear structure provides flexibility and easy processing. Polyethylene is a good illustration of a linear polymer.

- Branched Polymers: The properties are different, such as much softer or more flexible because of the side chains or branches on the major polymer chain. One excellent example is low-density polyethylene.

- Cross-linked Polymers: These polymers exist as an entanglement of chains and therefore form a three-dimensional network. That’s where cross-linking gives polymers more rigidness and stability in the forms of rubber or bakelite.

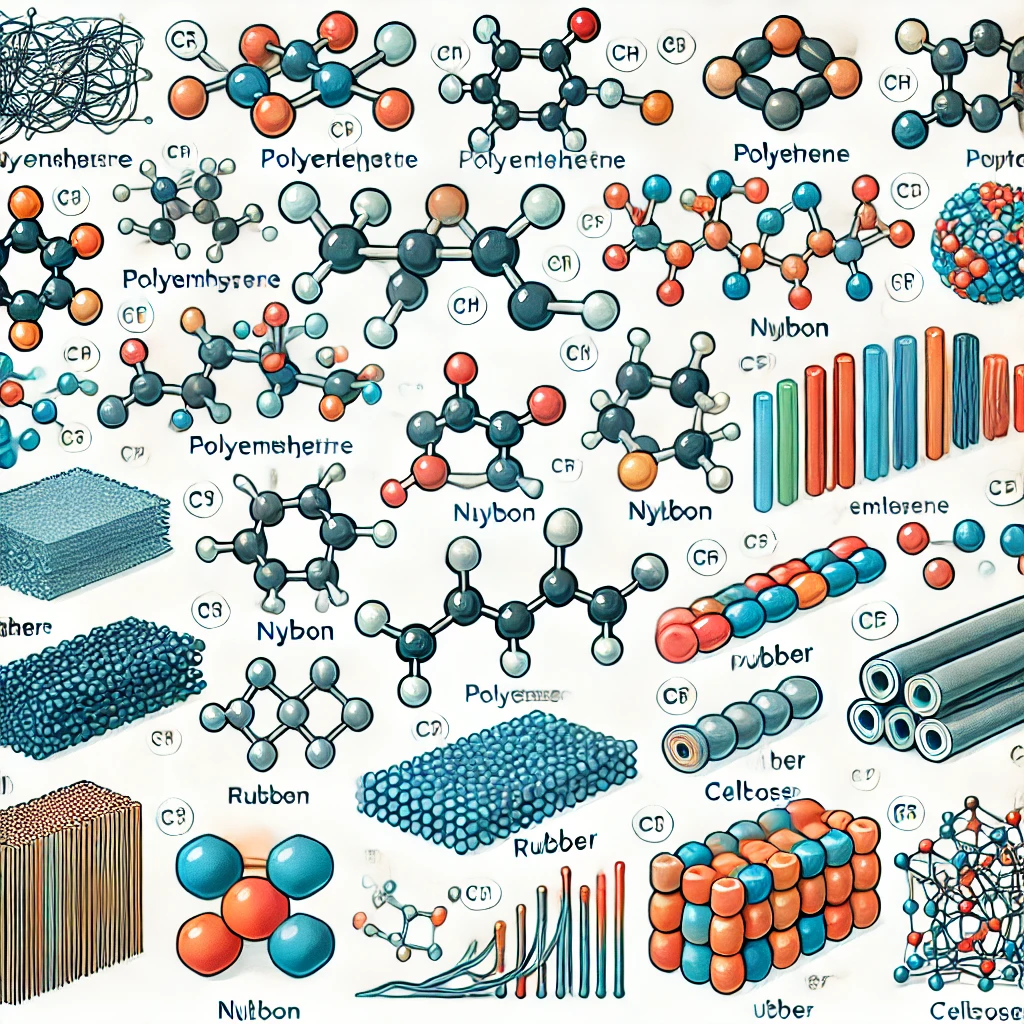

Polymers and Their Monomers

They are derived from smaller repeating building blocks called monomers. To describe polymer chemistry, one needs to understand the relationship of polymers and monomers, and monomers covalently bond to each other by forming chemical reactions to create long polymer chains.

For example, ethylene is the monomer that results in polyethylene at the end. The properties of the polymer are dependent on the nature of the monomer used in the process of polymerization. It could have strength, flexibility, or even resistance towards heat. Through the use of various monomers, different polymer result by changes in the composition of monomers to create polymer for different industrial applications.

Polymerization Reactions

Polymerization reactions are the chemical processes wherein monomers combine to form polymer. Among the polymerization reactions, there are two main classes, and each of them differs in affecting the properties of the final polymer.

Addition Polymerization

In such a reaction, monomers of unsaturated bonds often double bond, so there are no by-product formations in the process. All atoms present in monomers end up in polymer, so it is a highly efficient process. For example, polyethylene forms due to addition polymerization where molecules of ethylene combine without wastage generation.

Condensation Polymerization

This is a type of polymerization in which monomers react with the elimination of small molecules such as water, methanol, or hydrochloric acid. This reaction is often driven by the application of heat with the aid of catalysts. A perfect example is the formation of nylon, where water is the byproduct.

Molecular Mass of Polymers

The molecular mass of polymers is quite high, which largely depends on many factors, such as physical characteristics – strength, elasticity, melting point, and others.

Molecular mass as such is defined as the sum weight of a polymer chain. This sum weight depends primarily on how many monomers are linked together.

Methods of Measuring the Molecular Mass of Polymers

The molecular mass plays a significant role in the industrial applications of the polymers. Polymers having a higher molecular mass are stronger and more durable, whereas polymer with lower molecular mass can be processed and molded easily. There are various methods of measuring the molecular mass of polymer. They include:

- Osmometry: The measures a polymer solution’s osmotic pressure from which the molecular mass can be calculated. It is particularly useful in the case of lower-molecular-weight polymer

- Viscometry: From the viscosity of a polymer solution, one can draw the inference of the molecular mass because higher molecular mass polymer give higher viscosities

- Light Scattering: The technique takes the amount of light scattered from a polymer solution is proportional to the polymer’s molecular mass.

Polymers Properties

The properties of the polymer rely on their structure at the molecular level. The properties change with the type of monomers used the choice of the polymerization process, and so on. Major polymer properties include the following:

Mechanical Strength

Some polymer, like Kevlar, have high tensile strength, and hence it is suitable to be used for bulletproof vests along with other safety and security appliances.

Thermal Stability

Thermal stability refers to the resistance offered by a polymer to temperature. Therefore, some polymer remain stable at high temperatures without degrading or melting. For instance, PTFE or Teflon is highly resistant to heat, and thus, these materials are used in manufacturing non-stick cookware.

Elasticity

Some polymer, for example, natural rubber or elastomers, will have excellent elasticity. They can be stretched many times, and then they return to their original dimensions. Because of this property, they are used in such products like tires and elastic bands.

Chemical Resistance

The polymer such as polyethylene are resistant to a wide range of chemicals, which is why they are used for chemical storage containers and chemical piping systems.

These versatile properties of polymer have made them essential for practically every industry, be it textiles or construction, medicine, or aerospace.

Polymers Types

They are long chains of covalently joined molecules, primarily composed of repeated structural units called monomers. Polymer have a wide range of applications in many industries, including plastics and textiles, and they can be classified into several groups according to their composition and properties. These polymer come in various types depending on the physical behavior of heat and their molecular structure.

Thermoplastics

Thermoplastics are those kinds of polymer that soften upon heating and solidify when the temperature cools down. You can melt them several times without altering their physical properties. Manufacturers use examples of thermoplastics, such as polythene, polypropene, and polystyrene, for packaging, household utensils, and plastic bottles, respectively.

Thermosetting Polymers

Thermosets. Once set, thermoset polymer remain permanently rigid. They don’t soften in the presence of heat. They are most useful for high-temperature applications. Epoxy resins and bakelite are some thermosetting polymer. Manufacturers commonly use these as adhesives and electrical insulators.

Elastomers

Elastomers are polymer that behave elastically. That is to say, they have quite the capacity to stretch and then revert to their original shape. Rubber is probably the most common elastomer; you find it in tires as well as in flexible tubing.

Applications of Polymers

The applications of polymer are quite vast, touching virtually every aspect of modern life. The most significant applications include the following:

Plastic Packaging

Manufacturers largely use plastics like polyethylene and polypropylene in plastic packaging. Manufacturers utilize it to develop soft, strong, and lightweight bags, bottles, and containers.

Medical Devices

The medical sector uses polymer extensively. Manufacturers utilize polymer like PVC and silicone for their biocompatibility and sterilization properties. Manufacturers make syringes, gloves, and even implants from this polymer.

Textiles

Manufacturers use synthetic fibers, such as polyester and nylon, which are polymer, to make clothes, carpets, and other textiles. They are strong, resistant to shrinking, and low maintenance.

Automobile Industry

Polymers have found a great deal of applications in the automobile industry. Polymer lightweight and rigid materials are employed in automobile parts, bumpers, dashboards, and fuel tanks, reducing vehicle weight and therefore enhancing fuel efficiency.

Building Materials

The construction industry uses polymer as insulators, pipes, window frames, and flooring materials. They resist corrosion, yet are flexible and durable making it an excellent application in these areas.

Conclusion

The versatility and vast applications of polymer make them a necessity in modern life. Understand some of the classifications of polymer, their structure, and polymerization reactions to put into perspective much of what they represent in the industries. The selection of types of polymer depends on specific needs and requirements from molecular mass to mechanical and thermal properties.

| Polymers UPSC Notes |

| 1. Polymers are large molecules formed by repeating monomer units linked through chemical reactions called polymerization. 2. Polymers are classified based on origin into natural, synthetic, and semi-synthetic polymers, each with distinct characteristics. 3. The structure of polymers can be linear, branched, or cross-linked, affecting their flexibility, strength, and durability. 4. Polymerization occurs through addition or condensation reactions, which influence the polymer’s molecular mass and properties. 5. Polymers exhibit properties like mechanical strength, elasticity, thermal stability, and chemical resistance, making them versatile materials. 6. Polymers are used in various industries, including packaging, medical devices, textiles, automobiles, and construction, due to their adaptability. |