The cotton textile industry has been a cornerstone of the Indian economy, playing a pivotal role in its industrial and economic development. Today, India stands as one of the largest producers and exporters of cotton textiles, contributing significantly to the global market. The first cotton textile industry in India was established in the early 19th century, marking the beginning of an era that would see the nation emerge as a leading player in the global textile market.

- Employs millions across various segments, from farming to manufacturing, supporting livelihoods and rural economies.

- A significant contributor to India’s export revenue, showcasing the nation’s craftsmanship and quality to the world.

- Integrates advanced technologies, enhancing productivity and maintaining global competitiveness in the textile market.

What is the Cotton Textile Industry?

The Cotton textile industry encompasses the production, processing, and distribution of cotton fibers and fabrics. It involves a range of activities from growing raw cotton to manufacturing various cotton products. This industry is vital for producing a wide array of items such as yarns, fabrics, garments, and household textiles. It plays a crucial role in the global economy, providing employment and contributing significantly to GDP and trade.

Cotton Textile Industry: Historical Background

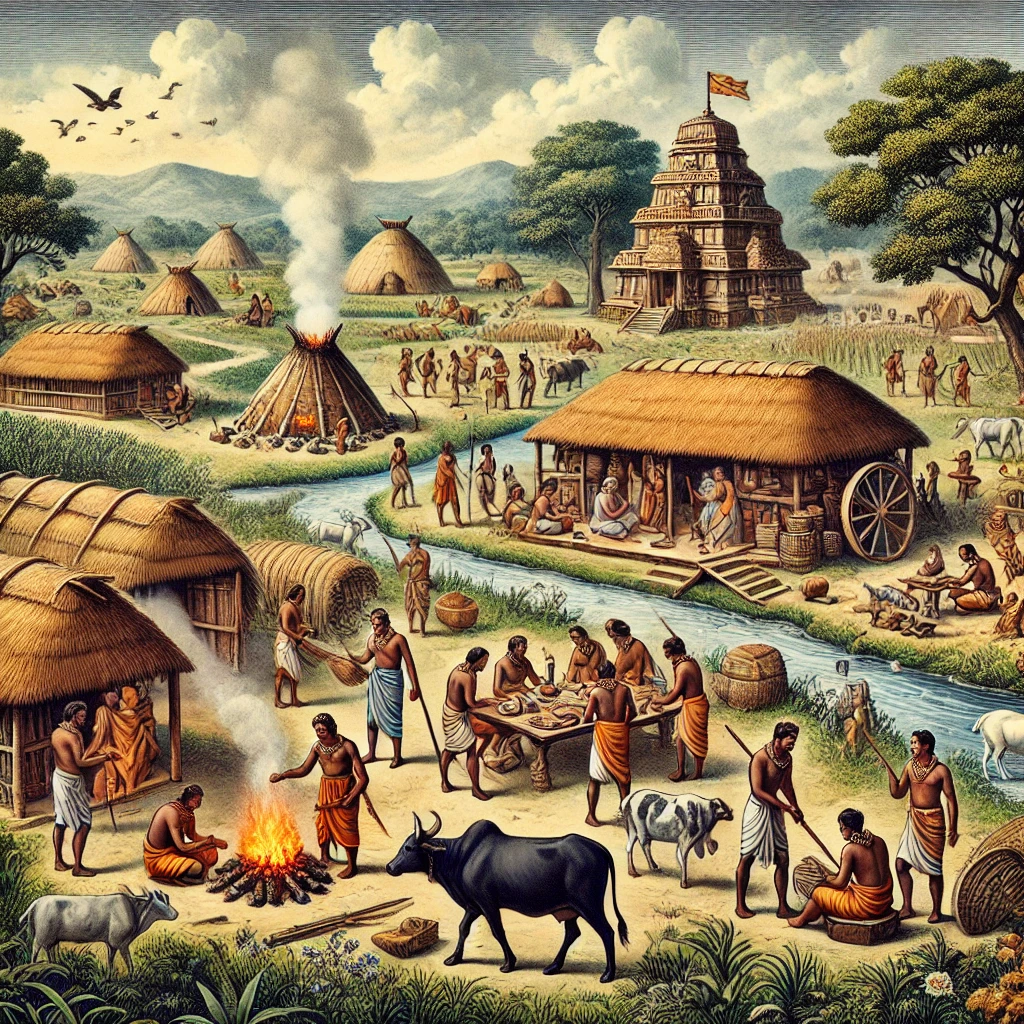

The cotton textile industry, with roots in ancient India, has played a pivotal role in the country’s economic and social development. Originating in the Indus Valley Civilization, it became a cornerstone of trade and industrial growth through the centuries.

Ancient Roots

The history of the Cotton textile industry in India is as old as the Indus Valley Civilization, where cotton fabrics were woven and traded. This ancient period showcases India’s long-standing expertise in cotton textile production, with archaeological evidence suggesting that cotton weaving was practiced as early as 3000 BCE.

Medieval Flourishing

During the medieval period, Indian cotton textiles continued to flourish, with regions like Gujarat, Bengal, and the Coromandel Coast emerging as major centers of production. Indian textiles, especially muslin from Bengal, gained international fame for their fine quality. The demand for Indian cotton textiles grew significantly during this time, establishing India as a leading exporter.

Colonial Era Expansion

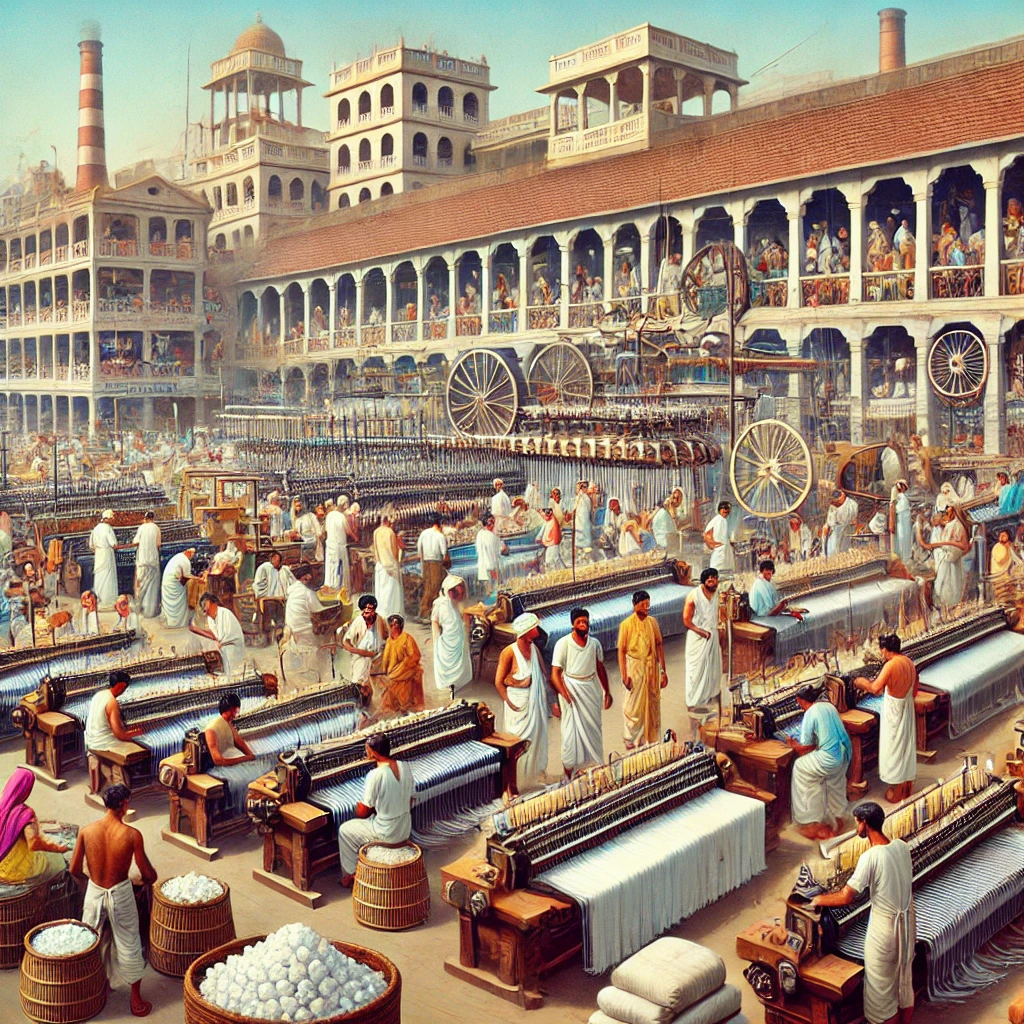

The advent of European trading companies in the 17th century, particularly the British East India Company, marked a new phase in the Cotton textile industry in India. The British recognized India’s potential as a source of raw cotton and a market for their finished goods. The establishment of the first cotton mill in Bombay in 1854 marked the beginning of modern industrialization in India.

Industrial Revolution and Technological Advancements

The Industrial Revolution in Britain had a profound impact on the Indian cotton textile industry. The introduction of mechanized spinning and weaving technologies revolutionized production processes, significantly increasing output and efficiency. However, this also led to the decline of traditional handloom industries as mechanized mills produced cheaper and faster alternatives.

Cotton Textile Industry: Growth

The growth of the Cotton textile industry reflects India’s industrial evolution, from ancient handlooms to modern automated mills. This sector’s expansion is driven by technological advancements, government support, and rising global demand, making it a cornerstone of economic development and a major contributor to employment and exports.

Early Beginnings

- Ancient Roots: Originated in the Indus Valley Civilization; cotton fabrics were woven and traded as early as 3000 BCE.

- Medieval Period: Flourished with regions like Gujarat and Bengal emerging as major production centers, exporting to global markets.

Colonial Era Expansion

- British Influence: The first modern cotton mill was established in Bombay in 1854.

- Proliferation of Mills: Rapid growth in cities like Bombay, Ahmedabad, and Calcutta during British rule.

- Technological Introduction: The adoption of mechanized spinning and weaving technologies increased production efficiency.

Post-Independence Development

- Modernization Focus: Post-1947, India aimed at rebuilding and modernizing the cotton textile sector.

- Government Initiatives: Policies and schemes were introduced to boost production and exports.

- Textile Hubs: Establishment of textile hubs and industrial parks in regions like Maharashtra, Gujarat, Tamil Nadu, and West Bengal.

Technological Advancements

- Automation: Shift from traditional handlooms to modern automated machinery.

- Power Looms and Spinning Mills: Enhanced productivity and quality.

- Advanced Dyeing Techniques: Improved the finishing and appeal of textiles.

Key Production Centers of the Cotton Textile Industry

The Cotton textile industry in India is geographically widespread, with several key production centers that contribute significantly to its output and global reputation. These centers, each with its unique strengths and specializations, play a vital role in the industry’s overall success.

Maharashtra

Maharashtra is a significant hub for the Cotton textile industry with key centers like Mumbai, Nagpur, and Solapur. Mumbai, where the first cotton mill was established, continues to be a major player in the industry. Nagpur and Solapur are also important, with Nagpur is known for its spinning and weaving units and Solapur for its handloom and power loom textiles.

Gujarat

Gujarat, often referred to as the “Manchester of India,” has major textile centers in Ahmedabad, Surat, and Vadodara. Ahmedabad is renowned for its numerous textile mills, while Surat is famous for both synthetic and cotton textiles, particularly in fabric processing. Vadodara is noted for producing cotton and blended fabrics.

Tamil Nadu

Tamil Nadu is another key state for the Cotton textile industry, with Coimbatore, Tiruppur, and Erode being the primary centers. Coimbatore, known as the “Manchester of South India,” excels in spinning mills and textile machinery. Tiruppur leads in knitted garment production, especially cotton T-shirts.

West Bengal

West Bengal, with Kolkata, Howrah, and Murshidabad, has a historical significance in the Cotton textile industry. Kolkata houses several mills, Howrah is known for its small and medium textile units, and Murshidabad is famous for traditional muslin and silk, along with cotton textiles.

Cotton Textile Industry: Challenges and Opportunities

The Cotton textile industry is a vital segment of the global textile market and plays a significant role in the economic fabric of many countries, particularly India. This industry has a rich history and a dynamic presence, yet it faces a multitude of challenges that threaten its growth and sustainability. These challenges range from competition with synthetic fibers to environmental and labor issues.

Challenges

- Competition from Synthetic Fibers: The rise of synthetic and blended fabrics presents a significant challenge to the Cotton textile industry. Synthetic fibers like polyester and nylon are often cheaper and more durable, leading to increased consumer preference.

- Fluctuating Cotton Prices: The Cotton textile industry in India is heavily dependent on raw cotton, and fluctuations in cotton prices can impact profitability.

- Environmental Concerns: Cotton cultivation requires large amounts of water and pesticides, leading to environmental degradation. Additionally, the textile manufacturing process contributes to pollution, raising concerns about sustainability.

- Technological Gaps: Despite advancements, there are still technological gaps in some areas of the industry. Smaller mills and traditional handloom sectors may lack access to modern machinery and technology, affecting their productivity and competitiveness.

- Infrastructure Issues: Inconsistent infrastructure development, particularly in rural areas, can hinder the efficient operation and expansion of textile units. Poor logistics and transportation facilities also add to the operational costs.

- Labor Challenges: The industry faces challenges related to labor, including skill shortages, labor unrest, and the need for better working conditions. Ensuring a skilled and motivated workforce is essential for sustaining growth.

Opportunities

- Sustainable Practices: The increasing global demand for sustainable and eco-friendly products presents an opportunity for the Cotton textile industry. Adopting organic cotton farming, water-efficient practices, and eco-friendly dyeing techniques can attract environmentally conscious consumers.

- Government Support: Various government schemes and policies aimed at modernizing the industry, such as the Technology Upgradation Fund Scheme (TUFS) and the Scheme for Integrated Textile Parks (SITP), provide financial assistance and infrastructure support to textile units.

- Rising Domestic Demand: With a growing middle class and increasing disposable incomes, the domestic demand for cotton textiles is on the rise. This offers significant growth potential for the industry to cater to local markets.

- Export Potential: India is one of the largest exporters of cotton textiles. Expanding into new markets and enhancing product quality can boost exports. Trade agreements and partnerships can also open up new avenues for international trade.

- Technological Advancements: Investing in advanced technologies such as automation, digital printing, and smart textiles can enhance productivity and quality. Embracing Industry 4.0 practices can help the industry stay competitive globally.

Cotton Textile Industry: Government Initiative

The Cotton textile industry is a crucial sector of India’s economy, providing significant employment and contributing to both domestic and international markets. To ensure its sustained growth and competitiveness, the Indian government has implemented a range of initiatives aimed at modernizing the industry, enhancing productivity, and promoting exports.

Technology Upgradation Fund Scheme (TUFS)

- Objective: To upgrade technology in the textile and jute sectors.

- Benefits: Provides capital subsidies for the installation of modern machinery, aiming to improve productivity and quality.

- Impact: Facilitates access to the latest technology, enhancing the competitiveness of the Indian textile industry globally.

Amended Technology Upgradation Fund Scheme (ATUFS)

- Objective: To attract investments in the textile sector by providing incentives for technology upgradation.

- Benefits: Offers a subsidy for machinery and equipment based on specific segments of the textile industry.

- Impact: Encourages modernization, which leads to higher efficiency, better quality, and increased production capacity.

Scheme for Integrated Textile Parks (SITP)

- Objective: To provide infrastructure facilities for setting up textile units.

- Benefits: Supports the development of textile parks with modern infrastructure, including roads, power supply, and water facilities.

- Impact: Helps in reducing operational costs and provides a conducive environment for textile manufacturing.

Make in India Initiative

- Objective: To transform India into a global manufacturing hub.

- Benefits: Offers incentives for manufacturing, including textiles, to boost domestic production and attract foreign investment.

- Impact: Strengthens the textile sector by increasing production capabilities and enhancing export potential.

Skill Development Schemes

- Objective: To provide skilled labor to the textile industry.

- Programs: Includes initiatives like the Integrated Skill Development Scheme (ISDS) and the Skill India Mission.

- Impact: Enhances the skill set of the workforce, improving productivity and quality of textile products.

Relevance for UPSC Aspirants

The Cotton textile industry holds significant relevance for UPSC aspirants as it embodies a vital component of India’s economic history, industrial development, and social fabric. Understanding this industry provides insights into the country’s colonial past, post-independence economic policies, and contemporary challenges and opportunities. Knowledge of the Cotton textile industry in India is crucial for subjects like Indian Economy, History, and Geography, and aids in comprehending broader themes such as industrialization, trade, labor issues, and sustainable development.

| Indian Cotton Textile Industry UPSC Notes |

| 1. The Indian Cotton Textile Industry is one of the oldest and most significant sectors in India’s economy. 2. It contributes substantially to employment, export earnings, and overall economic development. 3. The industry employs millions across various segments, supporting livelihoods and rural economies. 4. India is one of the largest producers and exporters of cotton textiles globally. 5. The industry integrates advanced technologies to enhance productivity and maintain global competitiveness. 6. Sustainable practices are being promoted, focusing on organic cotton and eco-friendly production methods. 7. The sector faces challenges like fluctuating raw material prices, competition from synthetic textiles, and international trade barriers. 8. Government initiatives like the Technology Upgradation Fund Scheme (TUFS) aim to modernize and support the industry’s growth. |